How Plan B Engineering Became a Client’s Plan A

The best ideas often come at inopportune moments. Nobel-winning scientist Paul Lauterbur scribbled the first idea for the MRI machine while eating at a local diner. Keith Richards heard the signature riff of “Satisfaction” in his sleep. He got up, played it into a tape recorder, then went back to sleep.

At Plan B Engineering, we have our own lore of a brilliant idea on a piece of scrap paper–a brown bag! Plan B’s principal and founder, John McErlean, was interviewed to get the full story.

Solving Complex Problems in the Kitchen

About six years ago, Plan B Engineering was hired to provide vertical shoring designs for some existing columns of an underground parking garage that were to be incorporated into a new highrise apartment building, now known as the Landmark II building in Los Angeles. While we were working on the shoring design, the General Contractor, MATT Construction, called John out of the blue and asked a series of questions about a much bigger problem. The new highrise required a large hole cut through four underground parking levels. Columns and slabs bordering the hole needed vertical shoring that was not yet designed, but the larger problem was the need to retain four floors–over 40 feet–of foundation wall against the pressure of soil and active streets that bordered the hole on two sides. The current bracing plan was stalled in reviews by city officials with no resolution in sight.

When discussing the current plans for the support of excavation bracing, McErlean told him the truth: “I wouldn’t do it that way at all.”

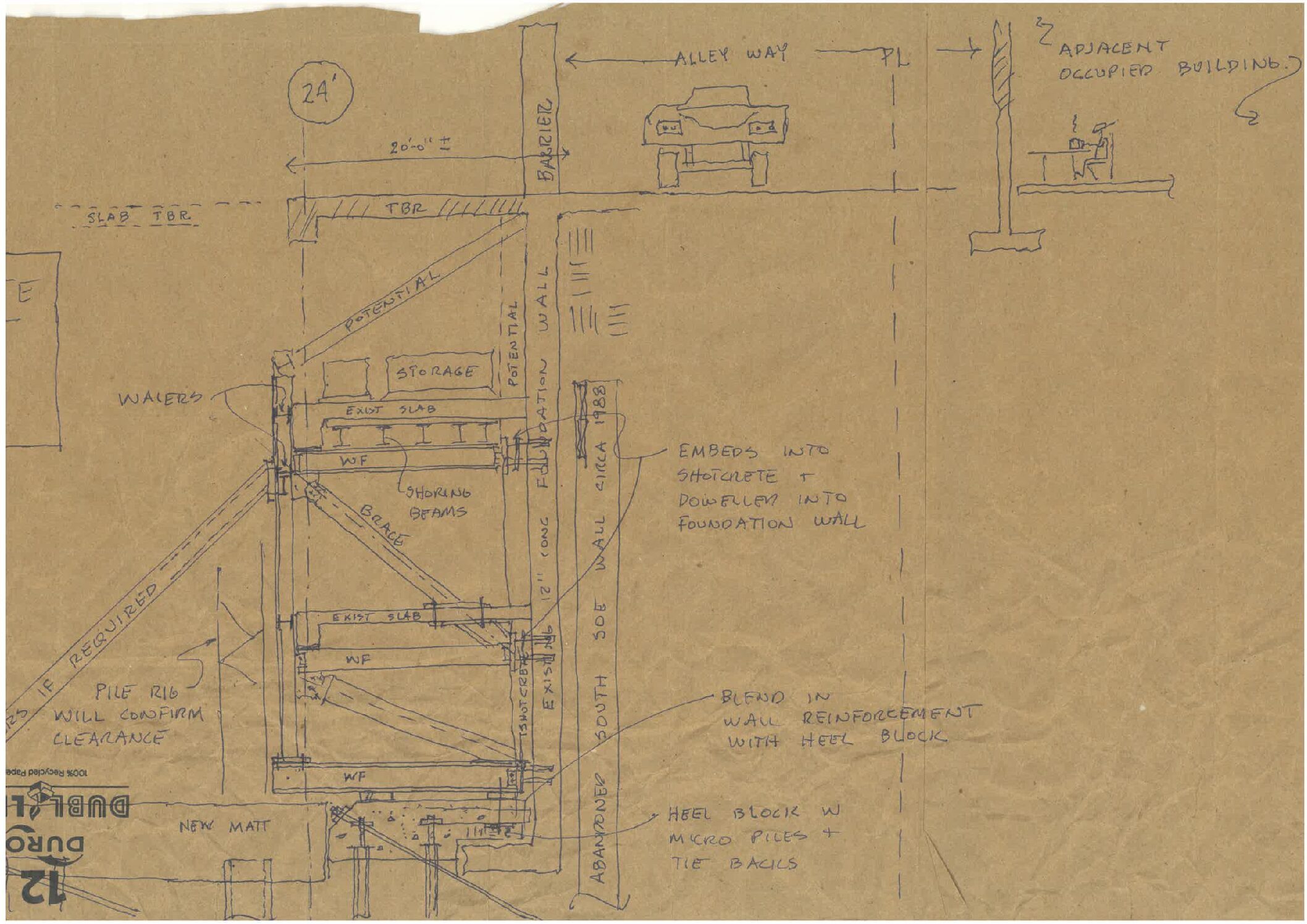

While daydreaming at his kitchen counter, with no sketchpad in sight, John cut open a brown paper bag and started sketching. He outlined all the considerations from a safety and logistics standpoint, including a major LA thoroughfare, alleyways, and nearby apartment buildings. He sketched out a braced frame system that could retain the foundation wall by repurposing the same floor slabs that had to be vertically supported. His idea relied on two decades of facade retention techniques honed in New York City, now blown up to LA-size proportions.

For clarity, McErlean emailed the picture of his paper bag to the GC. That picture was brought up in a presentation with the developer, Douglas Emmett, and discussed. The team immediately realized John’s sketch represented a new path forward that could keep the project moving. Within days, Plan B was engaged to finish the design, which started on a humble brown paper bag.

A Supersized Solution

John’s solution was to treat this below-grade bracing problem like a facade retention project back in New York City, only on a bigger scale. After all, holding up historic facades, floors, and roofs while coordinating with a new design is nothing new to Plan B. While soil loads increased the scale of the design, the strategy was well suited to work around a number of new building interferences and site constraints.

John’s idea used a series of steel brace frames to support 10ft wide strips of existing slabs that would remain and be reused as plan brace diagrams along the perimeter walls. Large soil anchors–some more than 50 feet long, carefully located to avoid adjacent foundations–and micropiles were used to resolve the huge overturning forces generated by retaining over 40 feet of soil and vehicle loads. Everything about this design was supersized, including the 250-ton proof loading of the soil anchors that was required by the City of Los Angeles. In the end, the final design was remarkably unchanged from the original brown paper bag idea.

Approvals in the City of Los Angeles

Developing a design that was both physically possible and structurally stable was only one piece of the puzzle. Plan B had to then submit the design for approval by the Los Angeles Department of Buildings and Public Safety. Fortunately, Plan B has decades of experience in New York City, one of the strictest jurisdictions for public safety regulations and construction enforcement in the country. This prepared our team well for gaining approval during a challenging and accelerated review process.

Now, the “brown bag” is an infamous story at Plan B Engineering, and the original paper bag is framed in the office.

Plan B Engineering: Out-of-the-Box Thinking for Creative Solutions

For the Landmark, Plan B used our experience coordinating complex existing building projects on the East Coast out west to solve a new problem. We looked at a foundation wall with over 40 ft of soil behind it, like a facade of a building. While soil loads are bigger than wind loads, the design approach worked perfectly for this below-grade bracing problem.

John, our principal and founder, saw the solution in his head and hurried to sketch it out. While we all thought he was a little crazy when he first brought this idea into the office, the talented engineers and designers at Plan B know a good idea when they see one. So, we took the concept and ran with it. What started as a spontaneous, stream-of-consciousness sketch became a “landmark” project in our company’s history. The “brown bag” highlights the creative and open-minded decision-making that defines the Plan B approach.

To learn more about our out-of-the-box engineering services and why so many of our clients choose to make Plan B their Plan A, contact us today.